Request of the customer

Our customer was looking for an ergonomic solution to assemble masks for oncology. Bringing together the necessary pin and sleeve was done manually, as well as pushing the assembly into the mask. This was very demanding for the operators' thumbs.

Our realisation

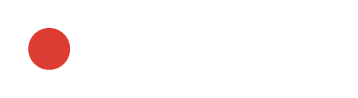

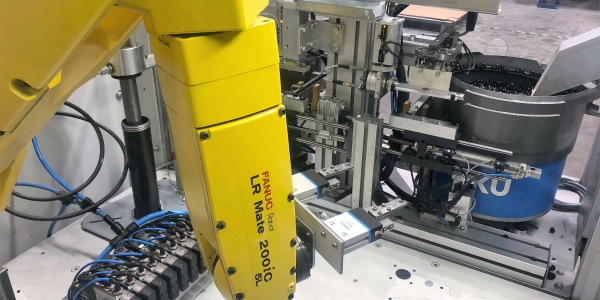

In collaboration with our sister company Matthys, we designed and built an assembly unit for the customer. Motiv was responsible for the electrical execution and control of the unit, including the integration of the robot.

The following production steps are carried out in the assembly unit:

- Separate vibrating troughs feed pins and sleeves

- A pneumatic unit provides 2 pins and sleeves to the robot

- The LRMate type Fanuc robot takes the pins, applies vaseline through a vaseline unit, pushes the pins into the provided sleeves and places them in a pusher unit

- Both pushpin assemblies are pushed into the mask by means of an air booster

Curious to know more?

Do you have questions about this realisation? Do not hesitate to reach out!